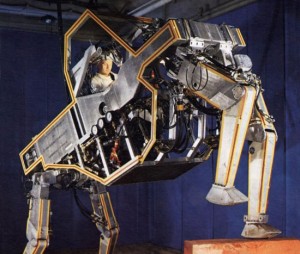

In 2017, MIT senior John Romanishin was advised by his robotics professor that his concept for self-assembling robots realistically could never work. Flash forward one year later, his tiny ‘modular’ robots are re-configuring themselves like Optimus-Prime.

So how exactly is this done? The answer lies in the physics of centrifugal-force, and precise mechanical engineering. The robots called ‘M-blocks,’ each contain a very tiny gyro-drive motor that can reach a rotational speed of 20,000 revolutions per minute. By comparison, a jet engine piston turns at 2,000-3,000 revolutions per minute. When the flywheel inside the block breaks, its angular momentum is transferred to the base of the cube. The edge of each cube is equipped with a small specialized magnet that is waiting for the other cube to arrive. All of this works in an instant to create the self-assembling modularity of the M-blocks, allowing them to climb, leap, fly through the air and align in a variety of arrangements.

“Modular construction is one of those things the robotics community has been trying to do for a very long time, probably from the first time someone saw Transformers over 30 years ago” Romanishin said. “They just needed a creative person who was passionate enough to keep going at it.”

The team at MIT see self-assembling robots being applicable in almost any industry.

” We see potential to create temporary modular structures for the space industry, the design industry, the engineering and construction industry on a worldwide scale. Anyplace where it is not easy to transport large amounts of materials our modular robots can potentially help…the applications of this type of technology are endless.”